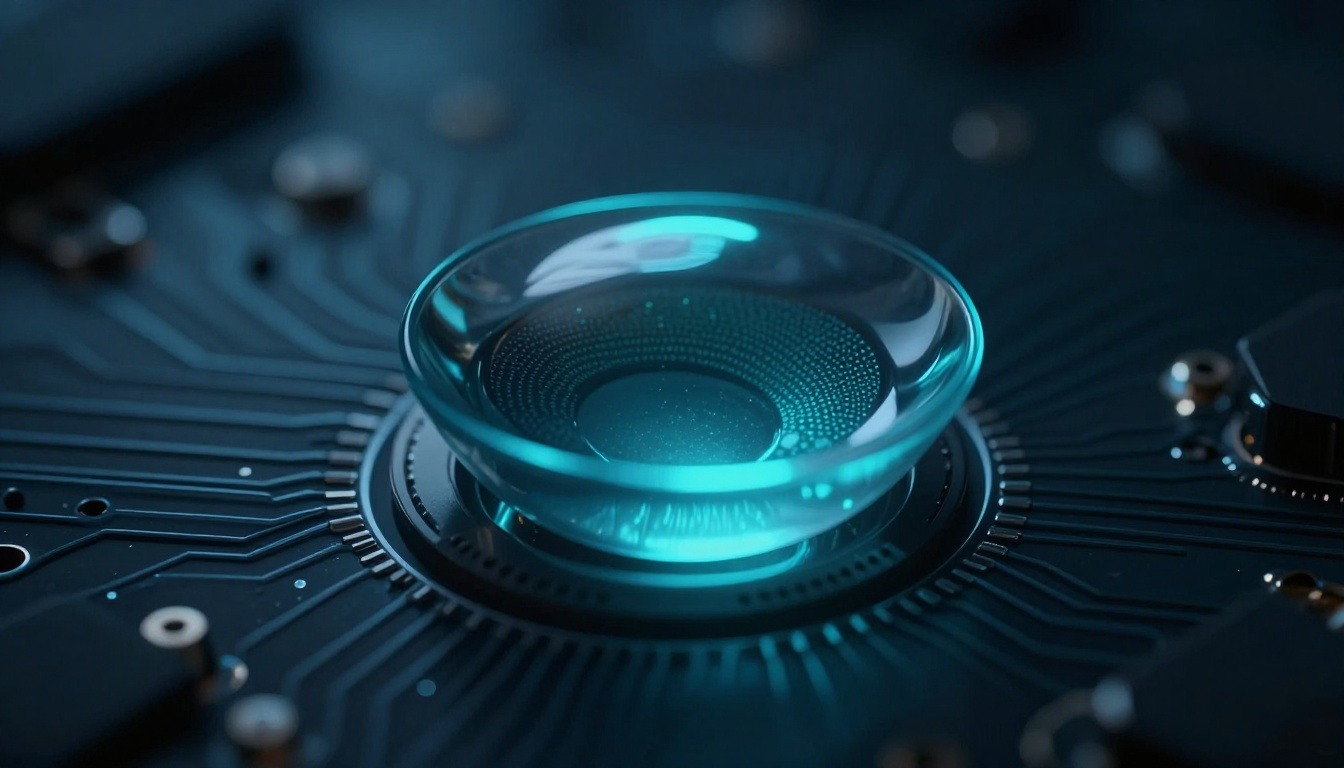

In factories and plants, a single seal failure can contacts durostech. Machines grind to a stop. Costs skyrocket from downtime. Extreme heat, harsh chemicals, and rough wear test every part. That’s where Duro-Tech steps in. They lead in advanced rubber and seal tech. Their Duro-Tech contacts, or seals, keep fluids and gases locked in place. These work best in cars, planes, and big machines. You get reliable performance in tough spots. Let’s explore how Duro-Tech builds seals that last.

Introduction: The Critical Role of Duro-Tech in Modern Manufacturing

Picture a factory line running non-stop. One weak seal bursts under pressure. Leaks flood the area. Repairs take hours, maybe days. Lives and money hang in the balance. Duro-Tech changes that game. They craft seals from top-grade elastomers. These hold up against brutal conditions.

Duro-Tech contacts mean tough, custom seals. Think O-rings or gaskets that fit exact needs. They shine in auto parts, flight gear, and heavy tools. No more guesswork. These seals boost safety and cut waste. Now, dive into the science behind them. See why factories pick Duro-Tech first.

Section 1: Understanding Duro-Tech Material Science and Composition

Duro-Tech starts with smart choices in materials. They mix polymers that fight off damage. This base sets their seals apart from basic ones. You get parts that endure longer shifts.

Proprietary Elastomer Formulations

Duro-Tech uses fluoroelastomers for top heat resistance. They add silicones for flexibility in cold spots. Why these? They handle swings in temp without cracking. The team blends in special fillers. This boosts strength and seals tight.

Compounding happens in controlled labs. They test mixes for exact traits. No off-the-shelf junk here. Each formula targets real-world stress. Factories see fewer breaks this way.

Resistance Profiles: Thermal, Chemical, and Abrasive Durability

Duro-Tech seals take heat from -40°F to 500°F. That’s key for engines and pipes. Chemicals like oils or acids? They resist without swelling. Abrasion from dirt or friction? These hold firm.

Compared to standard NBR seals. Duro-Tech lasts 3 times longer in hot oil tests. Viton types? Duro-Tech edges out with better flex. Data from lab runs shows 50% less wear. Your gear runs smoother, safer.

Manufacturing Precision and Quality Control Standards

They mold seals with injection tech. This keeps shapes exact, down to microns. Compression works for thick parts. No weak spots form. ISO 9001 certs back their work. Every batch gets checked.

Inspections catch flaws early. X-rays spot hidden cracks. This means zero defects reach you. Trust builds from consistent quality. Machines stay online.

Section 2: Key Applications of Duro-Tech Sealing Components

Seals from Duro-Tech fit many jobs. They solve leaks in fast-moving worlds. From roads to skies, these keep things tight. Pick the right one, and problems fade.

Automotive and Fluid Transfer Systems

Cars push seals hard. Fuel lines hit high pressure. Transmissions shift with heat spikes. Duro-Tech O-rings seal them all. Gaskets block oil leaks. Custom diaphragms handle pump pulses.

In a busy garage, these cut repair calls. One auto maker swapped old seals. Downtime dropped 40%. Drivers get reliable rides. No more roadside stops.

Aerospace and Defense Sealing Challenges

Planes face wild changes. Low air pressure at height. Fluids like Skydrol eat weak parts. Duro-Tech seals low-gas release. They stay firm in vacuum tests.

Defense gear needs the same. Missiles or jets demand zero failures. Validation runs prove it. Seals endure -60°F flights. Pilots count on this strength. Safety soars.

Industrial Machinery and Hydraulic Systems

Heavy loaders in mines chew through parts. Dust clogs, mud sticks. Hydraulic oils push seals to limits. Duro-Tech fits in joints and cylinders. They block grit and hold pressure.

Take Caterpillars. They use Duro-Tech in boom arms. One site cut seal swaps by half. Processing plants see less spill. Output jumps. Workers stay dry and safe.

Section 3: Design Advantages and Engineering Collaboration

Materials matter, but design seals the deal. Duro-Tech teams with you to fit seals right. They turn ideas into tough parts. Reliability follows.

Custom Molded Solutions vs. Standard Inventory Components

Stock seals fit basic needs. Custom ones from Duro-Tech match your setup. Engineers review CAD files. contacts durostech

Prototypes test quickly. Mold in days, not weeks. This beats generic parts that gap or slip. Your machine gets a perfect match. Performance peaks.

Enhancing System Reliability and Reducing Downtime

Bad seals mean stops. Duro-Tech acts as a shield. Pick compounds by load and fluid. Check seals every 500 hours. Swap if wear shows.

Managers save big. One tip: Match durometer to pressure. Soft for flex, hard for crush. Failures drop. Teams focus on work, not fixes.

Integration of Sealing Technology into IoT Environments

Smart machines use sensors. Seals must let wires pass without leaks. Duro-Tech materials play nice with tech. No corrosion from salts.

In 2026 plants, IoT tracks wear. Seals contacts durostech. Data flows clean. You spot issues early. Future setups stay sealed tight.

Section 4: Comparative Analysis: Duro-Tech vs. Conventional Sealing Materials

Why pay more for Duro-Tech? Basic rubber cracks fast. PTFE slides but lacks grip. Duro-Tech blends best of both. Value shows in use.

Longevity Metrics and Total Cost of Ownership (TCO)

Duro-Tech seals run 2-5 years in tough spots. Standard contacts durostech. Upfront cost? 20% higher. But swaps? You save 60% over time.

Say a pump station. Old seals fail yearly, $10k each fix. Duro-Tech? Every 3 years, $15k total. TCO wins. Budgets balance easily.

Performance Under Extreme Pressure Differentials

Pumps hit 5000 psi. Basic seals squeeze out. Duro-Tech resists extrusion. The compression set stays under 20%. Competitors hit 40%.

In plane actuators, pressure flips fast. Duro-Tech bounces back. No leaks mid-flight. Safety and speed hold.

Compliance and Regulatory Adherence

Food plants need FDA nods. Duro-Tech clears it clean. Military specs? They meet MIL-STD tough tests. No shortcuts.

Regs change, but these adapt. Audits pass smoothly. You avoid fines. Operations roll on.

Conclusion: Future-Proofing Sealing Integrity with Duro-Tech Expertise

Duro-Tech contacts deliver sure seals in rough worlds. Their elastomer smarts beat standard stuff. Apps span cars to factories. Long life cuts costs.

Key points stick: Top resistance, custom fits, easy IoT ties. Reliability saves time and cash. Don’t grab shelf junk. Talk to Duro-Tech engineers now. Solve your seal woes with pros. Build gear that lasts.